AI4Work

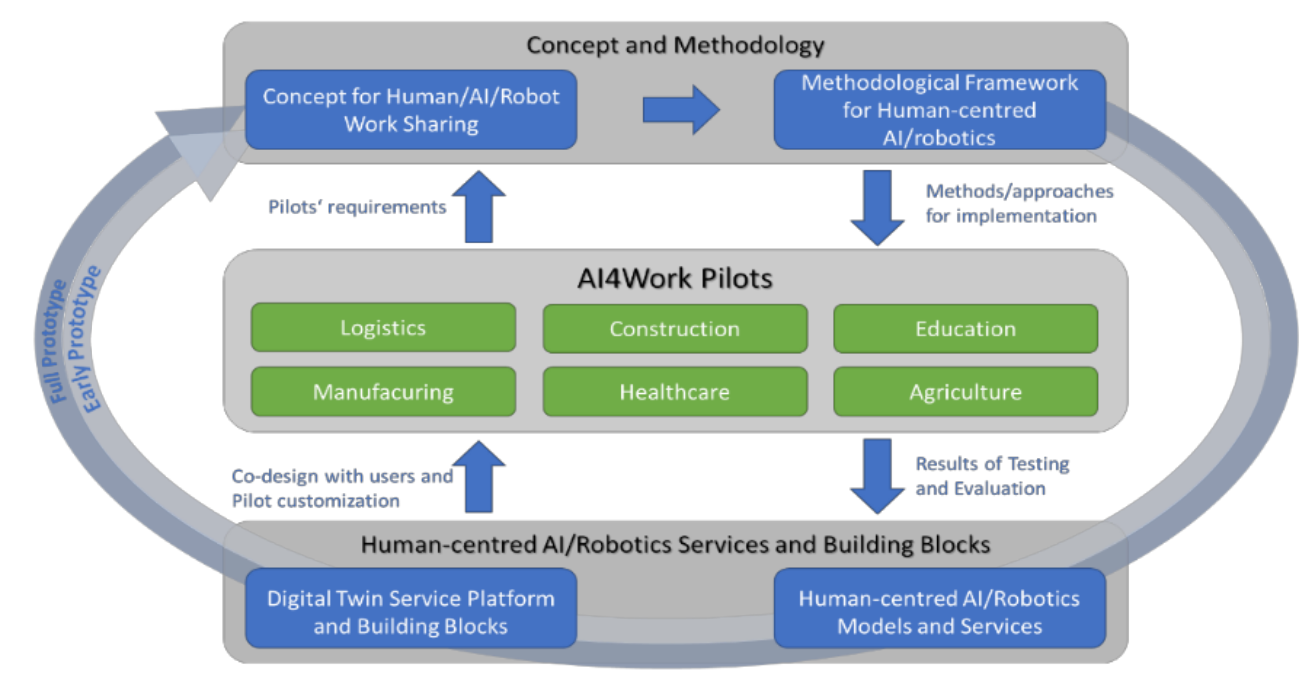

Human-centric Digital Twin Approaches to Trustworthy AI and Robotics for Improved Working Conditions (AI4WORK) aims to develop a set of methods and tools for Sliding Work Sharing between humans and AI/robotics services, ensuring optimal balance between human and machine activities depending on situational context, machine-based confidence levels, and human-machine interactions.

Motivations

- Workers are daily engaged in demanding manual tasks and complex decision-making activities in uncertain work environments where the context changes rapidly. These commitments increase stress levels and consequently reduce overall work efficiency.

- AI and robots can support human operators.

Challenges

- Guarantee acceptance of the AI/robots support.

- Facilitate a clear understanding of support, recommendations, or proposed decisions among human workers, ensuring alignment with their level of expertise and a thorough interpretation of the work context.

- Real-time adapt AI/robots support based on the current context thus maximizing efficiency and trustworthiness of proposed solutions.

Objectives

The main goal of AI4Work is to develop a methodological framework to support trustworthy AI and robotics to improve human workers’ conditions. It will include

-

A set of AI/robots Services for human-aware Task Planning, Planning Repair, Replanning and Monitoring to:

- enable human-aware long-term planning tailored to the operational context;

- facilitate users to comprehend and modify plans generated by the Task Planner;

- ensure the reliability of plans in uncertain conditions

-

A set of Building Blocks to:

- extract contextual information to guarantee the accuracy and reliability of AI suggestions and activities, while facilitating the acceptance of AI actions by the human users;

- evaluate the confidence level of AI decisions, ensuring optimal resource utilization, safety, etc., and enhancing user comprehension of proposed decisions.

- model human-robot/AI collaboration, facilitating seamless interaction and effective management of joint decisions.

-

A Digital Twin that simulates the human worker (e.g., current job and workcell, personal needs and skills, physiological parameters) and the machine (e.g., productivity and quality indicators, maintenance and setup status).

To demonstrate the generality of the framework, it will be applied and tested across a set of six pilots in heterogeneous domains:

- Logistics (OAS AKTIENGESELLSCHAFT - Germany);

- Manufacturing (I.M.A. INDUSTRIA MACCHINE AUTOMATICHE IT SPA - Italy);

- Construction (KUKA ASSEMBLY & TEST GMBH - Germany);

- Healthcare (DIAGNOSTIKON KAI THERAPEFTIKON KENTRON ATHINON YGEIA ANONYMOS ETAIREIA - Greece);

- Education (UNIVERSITY OF PIRAEUS RESEARCH CENTER - Greece);

- Agriculture (QUINTA DO CRASTO SA - Portugal).

General Info

Start Date: 1 Jan 2024

End Date: 31 Dec 2026

Duration: 3 years

Funding: H2020 - ID: 101135990

Partners

- INSTITUT FÜR ANGEWANDTE SYSTEMTECHNIK BREMEN GMBH (Germany) (Coordinator)

- FONDAZIONE BRUNO KESSLER (Italy)

- LAPPEENRANNAN-LAHDEN TEKNILLINEN YLIOPISTO LUT (Finland)

- UNIVERSITY OF YORK (United Kingdom)

- TTS TECHNOLOGY TRANSFER SYSTEMS SRL (Italy)

- RIJKSUNIVERSITEIT GRONINGEN (Netherlands)

- TURUN YLIOPISTO (Finland)

- UNIVERSITY OF PIRAEUS RESEARCH CENTER (Greece)

- UNPARALLEL INNOVATION LDA (Portugal)

- THE OPEN GROUP LIMITED (United Kingdom)

- CIRCULAR ECONOMY FOUNDATION (Belgium)

- BIOASSIST SA (Greece)

- OAS AKTIENGESELLSCHAFT (Germany)

- I.M.A. INDUSTRIA MACCHINE AUTOMATICHE IT SPA (Italy)

- DIAGNOSTIKON KAI THERAPEFTIKON KENTRON ATHINON YGEIA ANONYMOS ETAIREIA (Greece)

- KUKA ASSEMBLY & TEST GMBH (Germany)

- UNIVERSIDADE DE TRAS-OS-MONTES E ALTO DOURO (Portugal)

- QUINTA DO CRASTO SA (Portugal)